Versatility's fabrication engineering group collaborates closely with customers, ensuring that new products achieve the optimal design for the lowest manufacturing cost possible.

VTW’s experienced engineering staff works with the customer to create the best product, component or assembly possible. Whether this means designing something from scratch, providing feedback for a potential prototype, re-engineering an existing product, or even something simple like selecting a material, we can help. We provide the customer with the functionality, endurance and manufacturability they are looking for. Today’s fabrication technology, along with innovations in manufacturing processes continue to streamline our custom design work. VTW can integrate more secondary options into one continuous automated manufacturing process, thereby saving time, labor, and cutting costs that are passed onto customers.

VTW's Qstep® Process ensures engineering engagement on every project. READ MORE.

VTW's Qstep® Process ensures engineering engagement on every project. READ MORE.

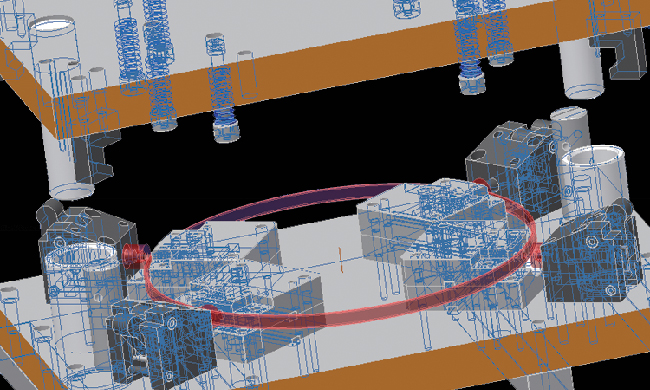

From Part Design to Re-engineering to Tooling and Fixture Development, VTW engineers can assist in saving you time and labor.

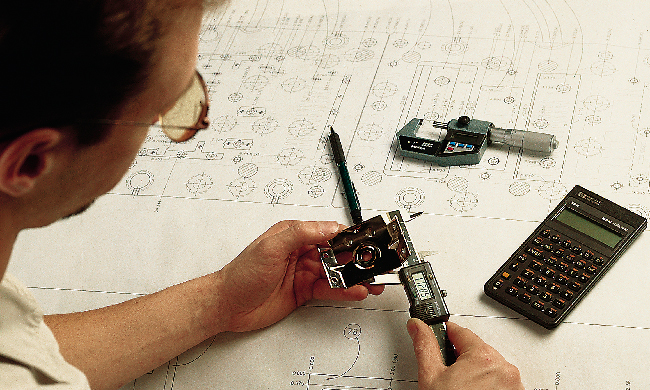

Testing and researching parts and product functionality

Testing and researching parts and product functionality

Improving precision, quality and saving you time

Improving precision, quality and saving you time

Engineering personnel uses Qstep®, our manufacturing customer engagement process, to drive a project's success by positively impacting quality, cost, and delivery. Versatility Tool Works and Manufacturing strives to be a true business partner by offering a spectrum of value-added services including tooling, design, engineering, state of the art manufacturing, and inventory fulfillment. Our engineering and design group helps you find innovative solutions, keeping to your timeline and improving product manufacturability and quality.

VTW Partners with Vendors to improve quality, function, longevity and component and assembly costs.

_650x390.jpg)